Technology is changing how factories work. Artificial Intelligence (AI) and robots are helping companies make things faster, safer, and cheaper. This blog explains how AI and robotics are improving manufacturing, their effects, and what the future may look like.

How Is AI Changing the Manufacturing Industry?

AI is making factories smarter. It helps machines learn from data, make better decisions, and work automatically. Here are some ways AI is changing manufacturing:

- Predicting Machine Problems – AI can warn when machines need repairs, preventing breakdowns.

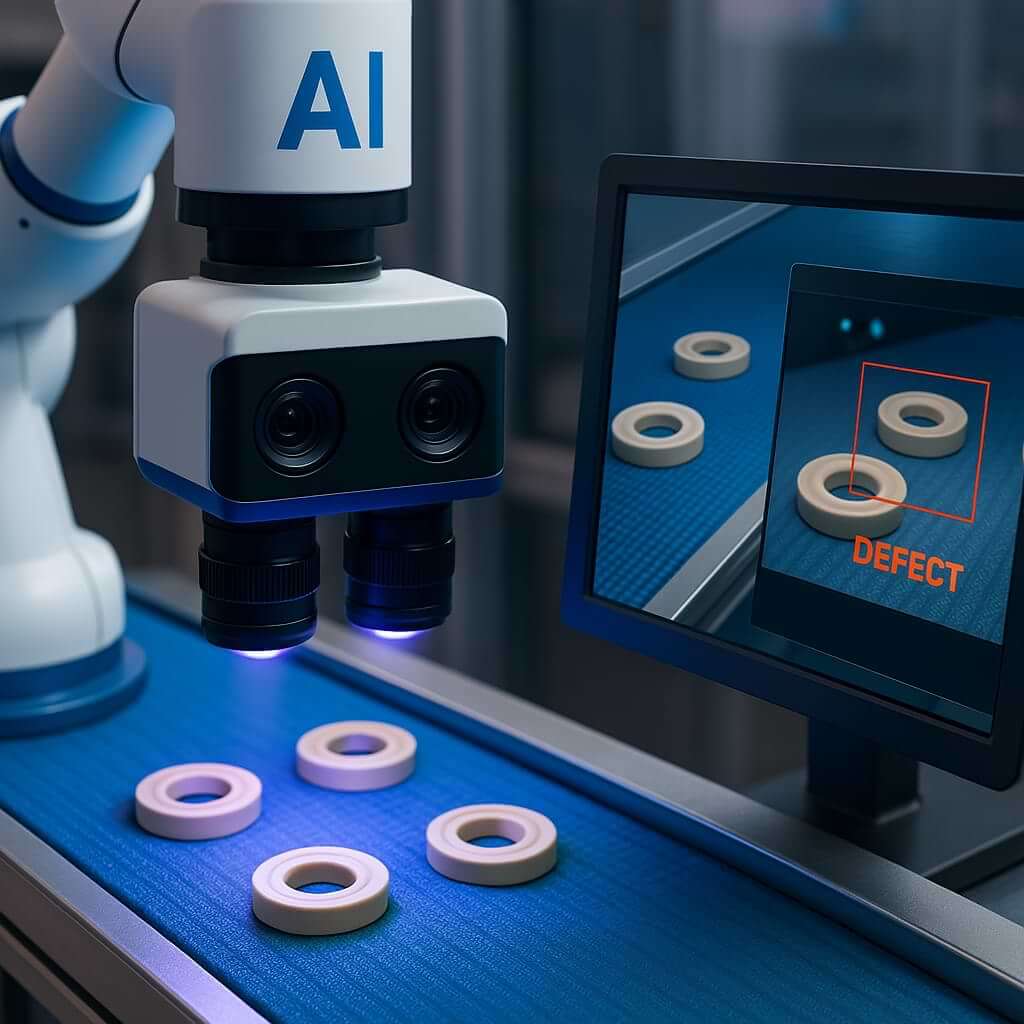

- Checking Product Quality – AI-powered cameras find mistakes in products.

- Managing Supply Chains – AI predicts demand and helps companies buy only what they need.

- Automating Tasks – AI-powered robots handle repetitive jobs, making work faster and easier.

- Custom Manufacturing – AI allows factories to make special, customized products quickly.

- Energy Efficiency – AI-powered systems optimize energy use, lowering costs and reducing waste.

- Better Workforce Management – AI helps assign tasks and schedule shifts for better productivity.

What Is the Impact of AI and Robotics?

AI and robots have transformed the manufacturing industry. Their impact can be seen in multiple areas:

- Increased Productivity – Robots and AI speed up production by reducing downtime and improving efficiency.

- Cost Reduction – Companies save money by reducing labor costs and minimizing waste.

- Higher Product Quality – AI-driven quality control ensures better accuracy and fewer defects.

- Enhanced Worker Safety – Robots handle hazardous tasks, keeping human workers safe from dangerous conditions.

- Better Decision-Making – AI analyzes data to help businesses optimize production and reduce risks.

- Global Competitiveness – Companies using AI and robotics can compete on a global scale with better efficiency.

What Is the Relationship Between AI and Robotics?

AI and robotics are closely linked but serve different functions:

- AI refers to software that allows machines to think, learn, and make decisions.

- Robotics involves building and programming physical machines to perform tasks.

- AI-Powered Robots – Many modern robots use AI to improve their performance and make independent decisions.

- AI Without Robots – AI is also used in data analysis, cybersecurity, and software automation without physical robots.

- Human-Robot Collaboration – AI and robotics are being designed to work alongside humans rather than replace them entirely.

Which Is Better, AI or Robotics?

AI and robotics serve different purposes, and neither is necessarily better than the other. Instead, they complement each other:

- AI is better for decision-making and problem-solving. It is used in software, automation, and data analysis.

- Robotics is better for physical tasks. Robots are ideal for handling repetitive or hazardous work in factories.

- AI-Powered Robotics combines both. This is the future of automation, where robots think and act independently.

- Industry Needs Determine the Choice. Some businesses need AI for analytics, while others need robots for physical work.

How Do AI and Robotics Affect Manufacturing?

AI and robots have a big impact on how factories work. Companies using them save time, reduce mistakes, and lower costs. Here are some key benefits:

- Faster Production – Machines work without breaks, increasing production speed.

- Lower Costs – Automation reduces the need for extra workers and materials.

- Better Safety – Robots handle dangerous jobs, reducing workplace accidents.

- Less Waste – AI helps factories use materials more efficiently.

- Smarter Decisions – AI helps managers improve production and fix problems faster.

- Higher Consistency – Robots produce identical products without variations in quality.

- Enhanced Human Productivity – Workers can focus on strategic and creative tasks.

How Are Robots Changing Manufacturing?

Robots are helping factories in many ways. They are getting smarter and more advanced. Here’s how they are changing manufacturing:

- Speeding Up Production Lines – Robots assemble products quickly and accurately.

- Working With Humans – Cobots (collaborative robots) work safely alongside workers.

- Organizing Warehouses – Robots move and sort items in large storage areas.

- 3D Printing – Some robots can build parts layer by layer.

- Quality Control – AI-powered robots check products to ensure they meet standards.

- Automated Packaging – Robots pack and label products, reducing human workload.

- Smart Transportation – Self-driving robots move goods within factories.

How Have Robots Affected Manufacturing?

Robots have brought big changes to factories. Some of the effects include:

- New Types of Jobs – Some jobs have disappeared, but new jobs in robot maintenance and programming have been created.

- More Output – Factories can now make more products in less time.

- Fewer Mistakes – Robots work with high precision, reducing errors.

- Flexible Workflows – Modern robots can switch between tasks easily.

- Energy Savings – Robots help factories use less electricity and materials.

- Increased Production Variety – Factories can produce different types of products efficiently.

- Safer Workplaces – Robots handle toxic and physically demanding tasks.

What Is the Future of Robotics in Manufacturing?

The future of robots in manufacturing looks exciting. As technology improves, we can expect:

- Fully Automated Factories – Machines will run entire production lines with little human help.

- Smarter Robots – AI will help robots make decisions and learn new tasks on their own.

- More Human-Robot Teams – Cobots will become more common in workplaces.

- Self-Driving Machines – Robots will transport materials and products without human drivers.

- Greener Factories – AI and robots will help reduce waste and energy use.

- AI-Powered Decision Making – AI will predict demand and adjust production automatically.

- Personalized Manufacturing – Robots will make customized products quickly and efficiently.

How Many Jobs Will AI Replace by 2050?

It’s hard to say exactly how many jobs AI will replace, but studies suggest:

- By 2030, up to 30% of jobs could be automated.

- By 2050, AI might replace 40-50% of repetitive jobs.

- New jobs will appear in AI programming, robot maintenance, and smart factory management.

- Retraining Will Be Important – Workers will need to learn new skills to work alongside AI.

- More Opportunities in AI Supervision – Humans will still be needed to oversee and manage AI systems.

While AI will change the job market, it will also create new opportunities for workers with the right skills.

How Do Robots Help Factories Be More Productive?

Robots help factories work faster and better in many ways:

- They Work Nonstop – Robots don’t need rest breaks, so production continues 24/7.

- They Reduce Mistakes – Robots follow instructions precisely, making fewer errors.

- They Speed Up Work – Automated systems complete tasks much faster than humans.

- They Free Up Workers – People can focus on creative and complex tasks while robots do repetitive work.

- They Improve Supply Chains – Robots help track and move inventory more efficiently.

- They Boost Accuracy – AI-driven machines measure and cut materials with extreme precision.

- They Reduce Costs – Fewer errors mean less waste, saving money on raw materials.

Conclusion

AI and robotics are changing manufacturing in major ways. They make production faster, safer, and more cost-effective. While some jobs will disappear, new jobs in AI and robotics will be created. The future of manufacturing will be a mix of human skills and advanced machines, making factories smarter and more efficient. Companies that adopt AI and robotics will lead the industry in the years to come.

As AI and robots continue to evolve, they will bring even greater changes. The key to success is adapting to this new technology, learning new skills, and working alongside intelligent machines to build a more innovative and productive future.

Enjoyed this blog? Share your thoughts below! For more exciting tech insights, explore our related blogs.

No responses yet